Poultry farmers are shifting away from straw and into wood shavings for their bedding, a trend that’s led Phillips Brothers, the 125-year-old family business, to branch into multiple new products with a focus on biosecurity.

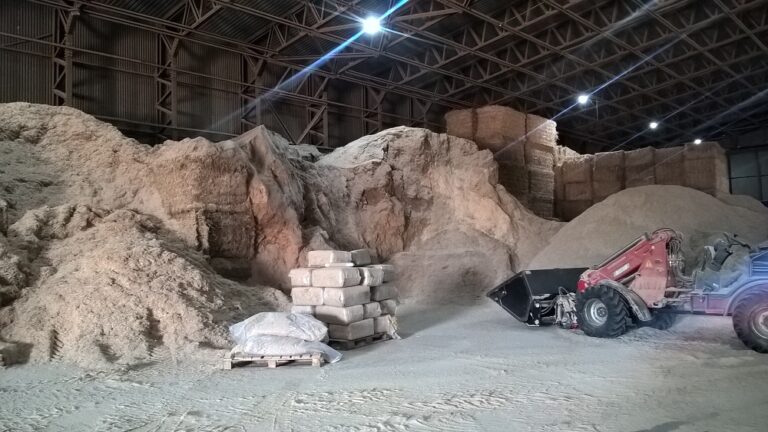

On a beautiful spring day in the Suffolk countryside, Paul Phillips is walking through his factory warehouse that’s packed with wood shavings, straw and compressed wood pellets.

Outside the sun is shining over the miles of arable fields, but inside the warehouse, machines are whirring, sorting stones and dust from straw and baling it into bedding for poultry, mixed in different volumes with wood shavings.

Phillips is a fourth-generation director of the 125-year-old family business, Phillips Brothers, which supplies 190 poultry farms across the UK. He runs the business with his sister Jane Knapp and cousin Ian Phillips. Some 90% of its products goes to poultry farms, with the remaining 10% split between pig, equestrian and pet bedding.

Despite its long history, Phillips has seen a boost in demand recently, driven by strong growth in the poultry market, leading to farmers investing in new poultry sheds and needing more bedding. And local demand in East Anglia is strong, he says.

The new Cranswick poultry processing plant, being built just a few miles away in Eye, is potentially great news for Phillips.

“By the end of 2019 their new factory will be processing 800,000 birds a week and then by the end of 2022 they will be doing 1.2 million a week,” he says. “We want to be part of that.”

He is seeing a lot of optimism in the poultry sector in East Anglia generally. “Our customers are all looking to expand and redevelop their sheds and refurbish sheds to make them better and they’re looking to increase the chicken they’ve got on the ground. We’ve already benefitted from Moy Park’s growth and especially in the East Anglia area, we see a lot of potential.”

“We aim to increase the number of farms we’re doing through our existing customer base and potential new customers like Cherry Valley and Crown [now owned by Cranswick] that we don’t currently do at the moment, and through private growers and to increase the product portfolio to supply different products.”

In recent years, the firm has invested in new equipment. Just over three years ago, it came to a head when the baling plant, although not old, was experiencing breakdowns and slow productivity. After-care from the supplier was slow and with no forthcoming solutions, so Phillips made the decision to invest in a new high spec automated baling plant with a significant increase in capacity.

“Following the installation, we added a new straw chopping plant and filtration system which addressed both improving quality and productivity levels of our straw based products,” says Phillips. “2018 saw the continuation of our investment plan with an upgraded wood shredding plant that shreds 100% clean recycled wood to meet a growing area in our product range with yet further investment in the plan for 2019. Each piece of plant playing a key part in enabling us to develop and introduce new products to our range.”

With new kit on board, Phillips Brothers now wants to increase the range of products it offers. Currently it offers pure wood shavings, straw and it uses shredded timber too to bulk it up. Different customers opt for different blends.

But it’s planning to introduce shredded timer as a product on its own because, says Phillips, the sector seems to be “moving more towards wood based products rather than straw”, partly due to better biosecurity credentials than straw, and partly because it has better absorbency and therefore is less of a risk against hock burn and pododermatitis.

Biosecurity is a major concern for the whole industry, and Phillips sees part of its role to help farmers keep standards tight. The biggest risk is still avian influenza, says Phillips, and due to this biosecurity is stringent. “Every delivery we have a risk assessment,” he says. “We have a biosecurity check list on every delivery that goes to farm. We’ve got full traceability of staff and product from supply to delivery, so we can be accountable for everything should AI come in, we can protect ourselves and the poultry industry.”

As further protection against the risk of disease, the bedding is all sprayed with SalGard to reduce the threat of salmonella. And 90% of the dust is taken out of the straw to protect the customers against the risk of aspergillus. “All straw is all barn stored. It is moisture tested on arrival and it’s moisture tested throughout the process and we probe it to make sure it’s under 15% because aspergillus doesn’t form below 15%,” says Phillips.

There are challenges for Phillips – one of the main ones is a general shortage of timber due to upheaval in the construction industry, partly Brexit-related, partly weather related. Last year’s wintry weather in spring meant the traditional season for garden sheds, decking and fencing was delayed, leading to a knock on shortage at timber mills where Phillips sources its materials.

But there is plenty of optimism too. The growth of the poultry sector, particularly in East Anglia, is cheering. And the business now has the fifth generation of the family on board in the form of Rhys Knapp, son of director Jane Knapp. He joined the business in 2015 and is currently production manager. The family has already started its succession planning for the next generation, and has more poultry farms in its sights.