Two new pieces of egg pasteurising kit are now available from Sanovo. The combination of the OptiBreaker Compact 2 and the skid-mounted StreamLine 1000-1/2 pasteurising unit offers smaller egg producers the opportunity to process ‘off-grade’ eggs into safe and convenient pasteurised egg products, the company said.

Traditionally, pasteurising eggs is an energy-intensive process and one that requires specially trained staff. But the StreamLine allows small-scale liquid plants to produce finished egg products, which have the same high quality as those from large processing facilities. And staff require minimal training to be able to operate the equipment.

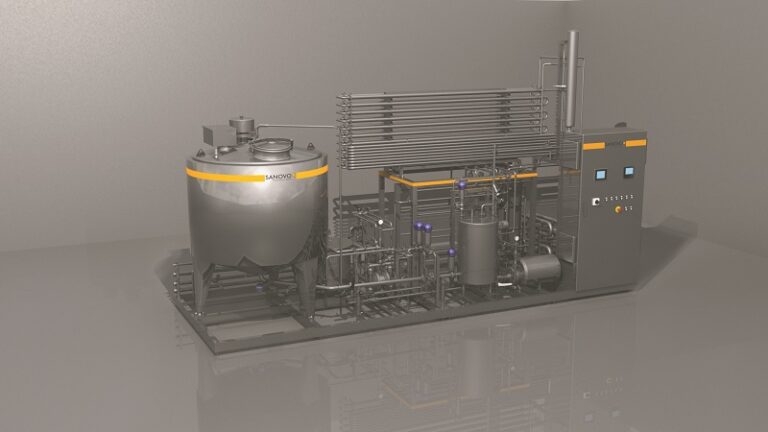

The egg pasteurising machine has capacity to process whole eggs and produce 1,000 litres of liquid egg per hour. The company says that the system is compact and easy to use and the skid-mounted unit, which has a small footprint, requires just a short period of operator training. It also offers producers the flexibility to produce special products such as organic egg, enzyme-treated egg or eggs with additives.

The unit is supplied ready for connection of all liquid product and utilities. These include product filling, water, lye, acid, steam, compressed air, ice water and the mains power supply to the control panel.

OptiBreaker Compact 2 egg breaking machine has the capacity to handle 21,600 eggs per hour – that’s 60 cases per hour. A filling station can be connected and liquid egg products can be fed directly into one, two, five and 10 litre plastic bottles, as well as larger containers.