Ishida Europe is launching a new version of its IX-G2 dual energy X-ray inspection system which is more sensitive in detecting low-density and difficult to spot foreign bodies, including bone.

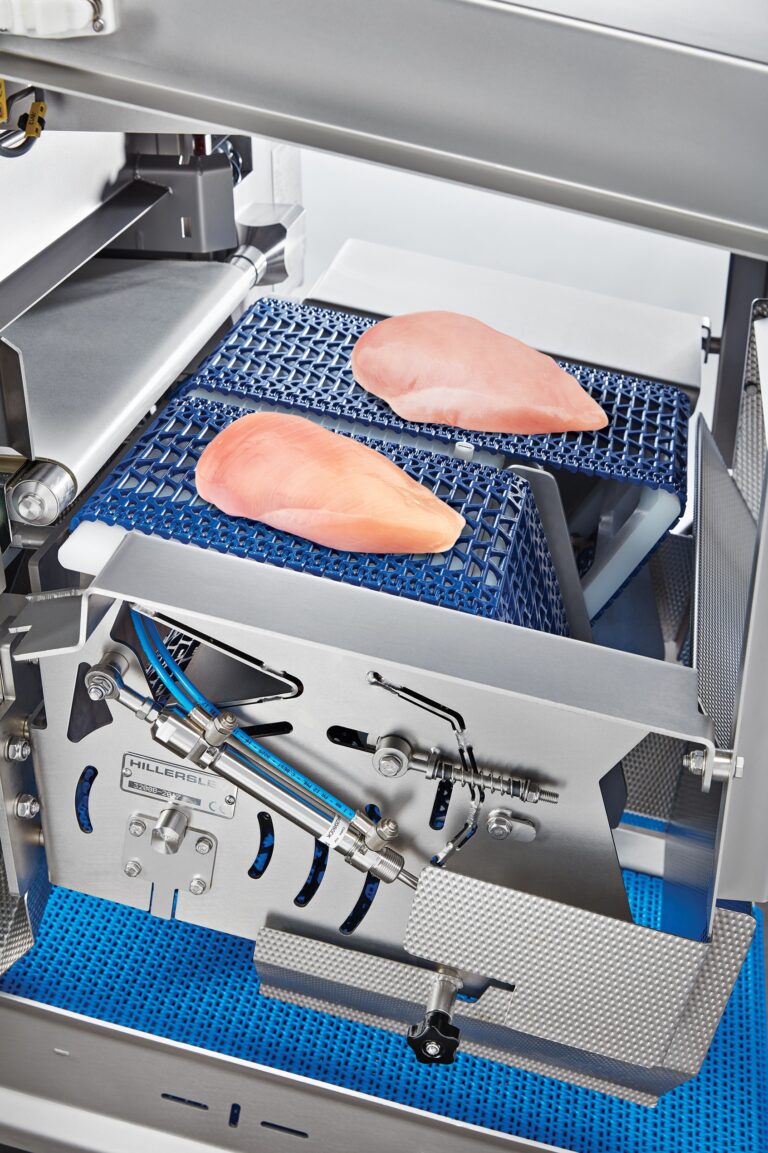

The Ishida IX-G2-F incorporates a new line sensor, which has increased the ability to detect bone fragments by a factor of four compared with previous X-ray models. This further increases the ability of the machine to identify contaminants, in particular when handling thicker and denser products such as chicken fillets, chicken breasts and a wide range of poultry products where they can often be overlapped or presented with uneven surfaces, the manufacturer said.

The enhanced sensitivity of the machine also greatly reduces the risk of false detections, which helps to maximise throughput and avoids the costs associated with unnecessary waste and the repacking of products.

“The enhanced sensitivity provides poultry processors with even greater reassurance that their high product quality standards are being maintained, and by minimising the number of false rejects, production can be maximised,” said Sibtain Naqvi, Ishida Europe’s X-ray product manager.