Using the novel concept of nanobubbles, the O2X machine can deliver a huge range of benefits to poultry, its inventors claim

Piran Bassett is a man who likes spending time in a shed. After several decades in the oil industry, he retired early with his “ill-gotten gains” to tinker and invent things.

But his retirement is now likely to be busier than ever, after a chance discussion over drinks with his friend Charlie Wellon in 2021 led them to invent a system that – they hope – will change the poultry industry forever.

Nanobubbles are a concept easy to describe but hard to fully grasp. But they are at the core of the invention.

Together they have built a machine that pumps billions of tiny oxygen bubbles into water – so tiny they are invisible – and this highly oxygenated water appears to have an astonishing range of benefits to poultry.

So impressive are the results, based on trials with five million broilers given the water through the drinker lines, that the system has now been installed on four UK farms and the innovative duo have the rest of the UK poultry industry (and indeed the rest of the world) in his sights.

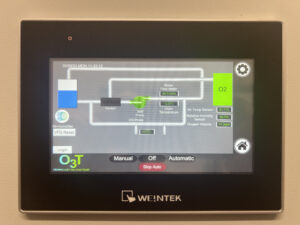

They named the machine O2X and, due to the unique properties and effects, refer to its output as super-water.

Oxygen

The story began when a poultry farmer at the drinks party asked a question. Was there a way to disinfect poultry sheds without using disinfectants?

This piqued Bassett’s interest. He wondered if highly ozonated (ozone being a form of oxygen) water could be made into a practical system to achieve this? However, during the development of this system there was a eureka moment.

Would highly oxygenated water disrupt the growth of bacteria in the drinker lines without the need for ozone?

“My theory was microbiota are monocellular organisms,” says Bassett. “They do not have the biochemical pathways to process extra oxygen, so if you increase the oxygen, what is going to happen to them?”

He used the analogy of a houseplant left outside in winter that dies because the environment has changed. Could excess oxygen could do that to bacteria?

Then a second – bigger – idea struck him. Could highly oxygenated water also benefit the birds? Basset was familiar with the idea that small increases in oxygen levels cause animals to grow better and suffer less disease, which is why sick people are often given oxygen masks.

“The hypothesis was that the extra oxygen would have great benefit to the birds and be detrimental to the undesirable microbes,” says Bassett. “Research shows that oxygen stress in all farmed animals is detrimental so it was clear a bit more oxygen would be a good thing.”

But how could it be done? “Conventional chemistry says oxygen levels in water cannot much exceed 10 parts per million (ppm),” says Basset. “But what if using some clever science and new technology the oxygen levels could be doubled, trebled or more?

“We thought the idea seemed so much fun that we would try it.”

The science bit

The project moved rapidly. In a nutshell the O2X development process was: start a company, find academic partners, get financial backing, find a test farm, build a prototype and test it.

“I reached out to old academic friends and thought this has got some legs,” says Bassett. “We’re going to have to do some things that conventional science says you can’t, but we know we can.”

In September 2021 he and Wellon registered the business under the name O3T. And aided by grants from the Low Carbon Opportunities Program, Innovate UK and academic support from Harper Adams University set about developing the ozone system and then moved on to the hyper oxygenation system, O2X.

But what exactly is it the machine does? In Basset’s words, it “strips” oxygen from the air and “introduces it into the water as nanoscale bubbles”. So small are the bubbles there are 766 billion of them in each litre of the “super water”.

But that description doesn’t really do it justice, because the bubbles are so numerous and so small they are “not really bubbles at all”.

Bubbles or not bubbles? That is the question…

Nanoscale objects are so small that they are beyond our physical experience, says Bassett. “Nanoscale gas bubbles do not behave like bubbles we are used to. They are neutrally buoyant and behave like a particle. They are also highly charged.”

Bassett says the correct term should really be nanoscopic oxygen particles.

The O2X machine generates billions of nanoscopic oxygen particles in the birds’ drinking water. According to Bassett, the nanoscopic oxygen particles (200 times smaller than a blood cell) travel through cell membranes directly into the cells of the organism to deliver their oxygen where it’s needed much more efficiently than blood ever can. “This is what causes the increase in health, betterment of FCR and the other benefits.”

The oxygen solution contains many more times the oxygen concentration that could ordinarily be carried by water.

The oxygen level in the water is increased 3.5 – 6 times beyond what conventional science has always stated as possible. “This oxygen supersaturation provides all the benefits,” says Bassett.

In September 2022 Bassett and Wellon installed the first full scale machine on a 250,000 bird farm.

Quickly the benefits became apparent. Improvement in various performance indicators, including halving mortality, improving FCR and even increasing thermal tolerance were noticed, but at this stage it was too small a sample to be conclusive.

“The first O2X crop broke all the on farm records,” says Bassett. “Since then, they have continued to enjoy fantastic crops.”

Field trials

Basset was keen to get data to back up the observations about the benefits.

Trials have now been taking place for two years and data has been made available from two broiler farms, comprising a data set from around five million birds.

With involvement some leading poultry vets including Daniel Parker of Slate Hall the trial results have demonstrated that O2X has provided more consistent finished weights crop on crop; more consistent and predictable daily weight gain, better bone strength, > 1.82% decrease in flock mortality, >0.38% reduction in rejects at factory, 0.046 reduction in FCR, and a 16-point uplift in EPEF.

In addition, post-mortems show additional bone strength in birds given the water. “We’ve banished leg issues,” he claims.

So, with these impressive results, what now?

Bassett wants to do business with as many poultry producers in the UK as possible, and also has his eye on expansion abroad.

And there is also the possibility of broadening the technology out into other sectors too.

In March 2023, the company was approached by one of the UK’s biggest growers of micro-salads. It wanted to know if the system could help it keep its 16 kilometres of irrigation lines free of biofilm and eliminate their having to use chemicals.

A system was installed in April this year and since then not only has the company eliminated chemicals, limescale and troublesome moulds but have also seen an uplift on crop yields, Bassett says.

Development is ongoing with trials set to begin with pigs and cattle later this year. And Bassett even has his sights on the potential for improving human health, with ideas about uses in hospitals and at gyms.

Investment

A company with ambitions as big as O3T’s and interest from numerous sectors needs significant investment.

Bassett is keen to stress the biggest investment to date has been the time and thought put into developing the system, including a vast amount of time and resources from his friends in academia and industry.

However, cash is also important in any start-up. The company’s initial investor got the ball rolling and since then, the company has been awarded grants from Low Carbon Opportunities Program, Sustaining Shropshire, which has awarded money on the basis of innovation likely to contribute to sustainability goals.

Additionally Innovate UK has provided extensive assistance and provided grants for securing the intellectual property. To date, there are 59 patent claims on this tech.

Sustainability

The system is not cheap to install, but Bassett says return on investment is speedy at less than 18 months. The cost is dependent on the size of the farm, but a four shed system over 11,000 sq m costs around £70,000 and a system covering up to eight sheds costs £80,000.

As well as the returns generated from improved broiler performance, Bassett is keen to emphasise the carbon savings of the product too.

“Due to the savings in feed, elimination of chemicals, uplift in bird health, reduction in rejects, our university friends estimate that full adoption of O2X yields a national carbon saving of > 1.8 million tonnes per year in the poultry sector alone,” says Bassett. “All of these outstanding benefits are brought from a small amount of electric, air, and a lot of innovation.”

Not all plain sailing

There have been some significant challenges along the way, though, he acknowledges.

“This was all new, so new we had to work with academic partners to describe new physics to accommodate the understanding, new instrumentation techniques to measure what was going on.

“We had to work with vets to derive protocols ensuring animals welfare. We had to work with the aerospace industry for fluid mechanics modelling, defence contractors for manufacturing and so the list went on.”

Two men in a shed

This was all hard, because, as Bassett explains, the company is “really just two blokes in a shed with a limited budget”. The key, he says, was to be able to describe the idea and goals to decision makers in the organisations in the hope we might persuade them to help “hopefully for free”.

This was where the success kicked in. “Nearly all the organisations we approached shared our enthusiasm and vision, helped above and beyond what we could have hoped for and got us to going.”

But with four commercial systems already in place, Bassett believes the sky is now the limit. “We are rolling this out commercially. We have done our trials, we have our data set, all of which is proving consistent and significant and verifiable uplift,” he says.

“At the moment we can build two a week. But we have international interest as well. I have heard from people in Australia who want to adopt this and there is also interest from the US.”

Right now, the partners are weighing up whether to seek further investment to enable a rapid expansion, or to grow organically. But while the path to growth is not yet mapped out, it’s clear that for someone who likes tinkering in a shed, Bassett’s retirement plans are very much on hold.