As poultry producers battle with aggressively rising costs, Michael Barker looks into the numbers behind the energy crisis.

If there’s one thing sapping the energy out of poultry suppliers right now, it’s energy bills. Swingeing increases in the cost of gas and electricity are combining with the worst year of avian flu, labour shortages and low returns to make this a time of challenge like no other.

As the impact of the Ukraine war sends already-rising fuel and energy costs through the stratosphere, businesses are trying to keep their balance sheets in check at a time of huge volatility.

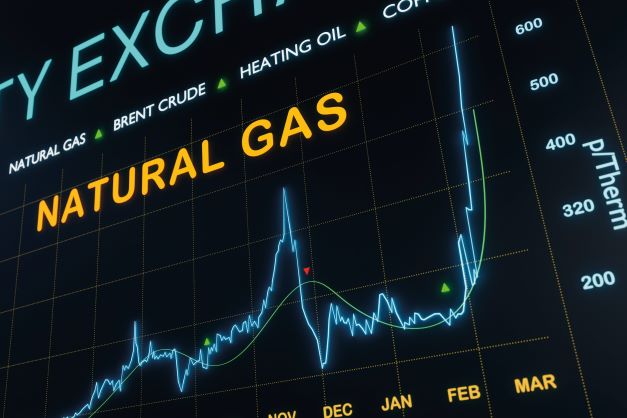

Will Foote, raw material manager at ForFarmers, put it succinctly when he described the input cost pressures as ‘a nightmare’. A look at the numbers lays bare the full extent of what farmers are having to deal with. Ofgem data show that electricity prices on forward delivery contracts have risen from £53/MWh on February 1 2021 to £413/MWh on July 25 2022, the latest available figures. Gas prices went up from 48p/ therm to 421p/therm over the same period.

The impact of that on the industry has been profound. A new report by the Association of Independent Meat Suppliers details the case study of a vertically integrated poultry business that has recently renewed its energy contract. Its day usage price has soared from 13p on the current contract to 65p on the new one – a 398% increase, while night usage is up 500%, from 10p to 61p.

Staggeringly, standing charges are up from 95p to 1,405p on the new contract – a 1,384% increase. All in, the poultry business expects its monthly electricity cost to jump from £22,000 to over £118,000.

“This will have a massive effect on our business,” the finance director at the poultry business – which was not named – said. “As things currently stand we can’t pass these increases to customers as they, in turn, wouldn’t be able to increase their selling prices to the consumer.”

Expensive energy increases the cost of production, and there are multiple factors playing into the mix. Foote points to the high price of Brent crude, which is selling at $93 a barrel, having reached $120 in the immediate wake of the Ukraine war.

“Higher energy directly increases the cost of production, processing, shipping and transport for the raw materials that go into the feed,” explained Foote. “Less obviously, higher energy also indirectly supports grain prices because of the link with biofuels, and also because of the commodity family link. Sterling is also very weak, which increases the cost of raw materials.”

It’s not a pretty picture, and there’s pressure on the Government to help. New prime minister Liz Truss announced a six-month energy support scheme for businesses earlier this month, offering equivalent support to that offered to consumers, and promised ongoing focused support for vulnerable industries after that.

Alongside this, it set up a new Energy Supply Taskforce and Energy Markets Financing Scheme aimed at reducing the cost of energy and bringing more stability to the markets, as well as promising to accelerate domestic energy supply, increase the UK’s energy resilience and make the UK an energy exporter by 2040.

“The energy package announced by the Government is welcomed to a degree, however a six-month cap for businesses is too short a time horizon,” said Mark Tufnell, president of the Country Land & Business Association. “A cap on the unit rate makes sense, but the Government must act to stop the increase in standing charges.

Members’ data shows that there is no real competition in the energy market, and this needs to be reviewed urgently. In the meantime, immediate cutting of regulations on renewables such as small-scale solar and business rate holidays are just a few examples of what could be done to ease pressures being faced across the countryside.”

One of the big industry frustrations with the business support announcement has been over a lack of detail. In particular, the farming industry wants to know whether it will be classed as a “vulnerable industry”.

“Our farmers are doing all they can to continue producing high-quality, affordable food, but we need confidence that this new Government is backing British food and farming and, crucially, reflecting that in its policymaking,” said NFU president Minette Batters. “This is essential now and beyond the initial six-month scheme and will require the farming industry and the Government to work together to develop targeted support across all farming sectors.”

It’s not even just gas and electricity that are a problem right now. 2 Sisters founder Ranjit Singh Boparan warned this month that consumers are set to be “held hostage” with upcoming price rises as the ongoing CO2 shortage sends production costs further north.

2 Sisters’ analysis noted that the UK uses approximately 2,000 tonnes of CO2 a day, and with plants in Billingham and Wilton due for imminent closure, that accounts for 1,300 tonnes alone. The current import capacity from Europe is around 600 tonnes, resulting in a huge supply squeeze and a £1 million a week on-cost. “This is a very serious situation we are facing,” Boparan added. “Once again, UK food security is under threat and the shopper ultimately loses – we simply have no choice other than to pay to keep supply. C02 suppliers are saying these increases happen immediately. They say it’s a take it or leave it situation.

“When poultry cannot be processed, it means birds must be kept on farms where there is a potential implication for animal welfare. The overall effect is welfare is compromised, and there is a reduced supply. My businesses are resilient, and we will navigate our way through this current CO2 crisis in partnership with our customers and suppliers. But make no mistake, negotiation is not an option here with the suppliers.”

Boparan, describing it as a national security issue, called on the Government to regulate the CO2 market or at least consider price capping. Government intervention will certainly offer relief, but industry leaders are also united in their view that what must happen is that retailers increase their returns to suppliers. If not, the inevitable outcome is more business failure, and at a time when the Food Strategy calls for more food self-sufficiency, that is not a palatable outcome for anyone.

ADDRESSING ENERGY USE IN EGG PRODUCTION

NFU Energy’s Claire Harty said that solar panels for barn roofs are ideal for poultry farms to mitigate the costs of fans, feeding and cleaning systems over the summer. She detailed how NFU Energy worked with an egg production business, based around four laying houses for 13,500 hens and rearing two batches of 6,500 chicks per year.

The company had invested in solar PV in 2011, and commissioned an audit recently to look into extended solar generation to cover the remaining electrical supply on site. NFU Energy’s report evaluated the feasibility of such a project and also suggested improvements to energy efficiency that could be implemented first. It established that the business used a total of 43,900 kWh per year, and the main energy users were: lighting and ventilation in four laying houses and a rearing shed; egg washers and egg collection belts; heating in the office and shop; heating in a holiday let; domestic use in the farmhouse, including a hot tub; incinerator; refrigeration, in the shape of two chest freezers.

Its recommendations were:

Fans: By controlling speed in response to changing indoor temperature, considerable amounts of energy can be saved. Fans may be operated at lower speeds during cooler periods.

Lighting: Optimal lumen output to mitigate undesirable behaviour in the flock but reduce spend.

Egg washer: Recommendations on operating times and insulating parts to bring down costs.