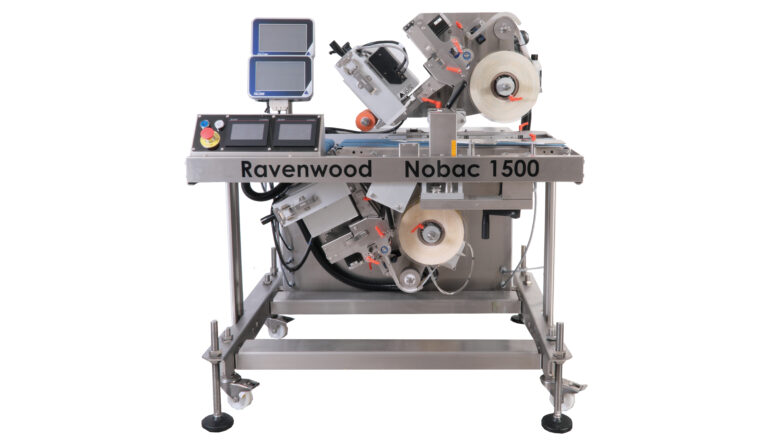

A new linerless labelling machine is promising a cost-efficient and high-speed alternative to standard self-adhesive top and base labellers.

Ravenwood is offering the Nobac 1500 as a standalone unit with an integrated conveyor. The applicator, designed for high-speed Modified Atmosphere Packaging (MAP) in the meat, fish, and fresh produce industries, is capable of printing and applying both top and base labels, or applying labels solely to the base, according to the company.

For standard MAP packs, the 1500 achieves faster labelling speeds, reaching up to 140 packs per minute.

The machine’s air-free operation not only cuts down on energy costs but also minimises expenses related to wear and tear on components, Ravenwood said, adding that the labeller has been fully tested to handle linerless materials that are 25% more economical on average compared to traditional self-adhesive labels.

Dave Mathison, Ravenwood’s Scotland and Ireland sales manager, said: “The 1500 is exceptional because it operates without the need for compressed air and can handle lower gsm materials. We are continuously developing new materials, with a focus on further reducing costs, including those with improved water resistance.

“The new labeller offers considerable CO2 savings and can be integrated with a weigh price labeller, optimising production throughput, efficiency, and flexibility for catchweight, fixed weight, or average weight labelling – ensuring products are retail-ready.”

The CO2 reductions come as linerless labels adhere to themselves on the reel using corresponding strips of adhesive and silicone, Ravenwood explained, eliminating the need for backing paper and so reducing material consumption. Backing paper generated from self-adhesive label application is typically sent to landfill.