Rising global temperatures mean producers must investigate solutions to keep birds cool, says housing specialist Val-Co

With average global temperatures rising, poultry is increasingly feeling the heat. Poultry cannot sweat like mammals and rely on different methods to keep cool to prevent heat stress. Therefore, all aspects of poultry management relating to heat stress should be reviewed.

One way is to incorporate a system for cooling either by a retro fit within existing houses or designing new sheds with an element of cooling built in.

One possible solution is a misting system which together with a well set-up ventilation system would help control heat at certain times of year.

Perhaps a more permanent solution would be the use of a cooling wall inbuilt and incorporated at the design stage and would involve a change of how producers look at their ventilation systems.

This is not a new technology but is a cost-effective way to control rising temperatures within poultry sheds, especially here in the UK.

Val-Co BV have both these systems available and are seeing an increase in enquiries for the pad cooling system and its benefits not only to control heat but also as a management tool to maintain a constant desirable temperature for maximum bird comfort.

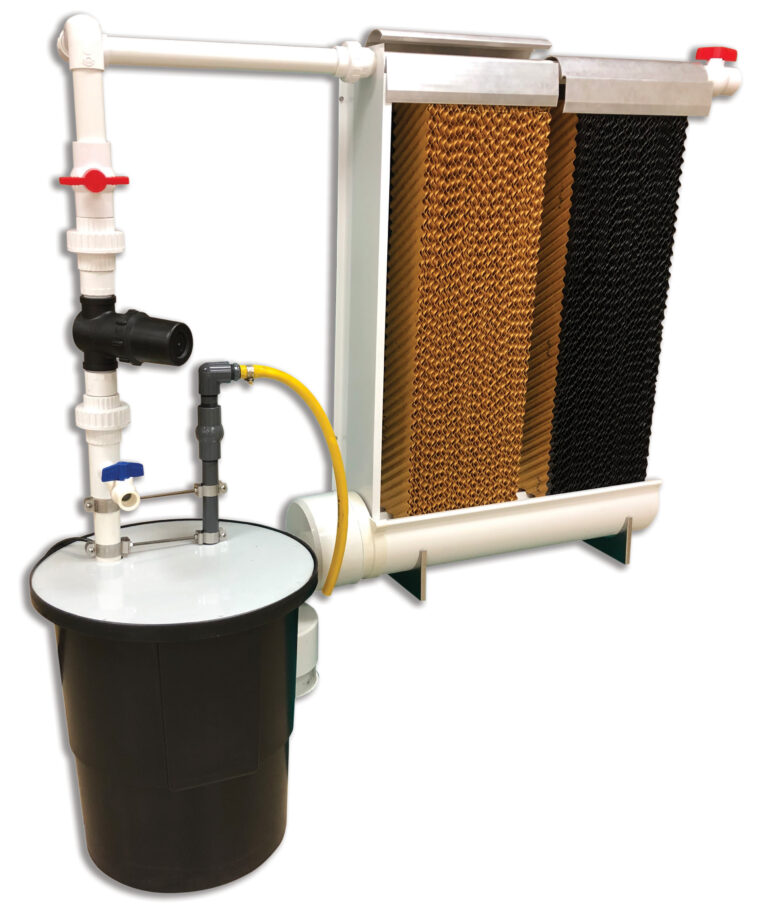

The Oasis system can be built into a shed side, flush or offset, giving a degree of choice for a retrofit into existing sheds (dependant on ventilation system and airflow). Pad cooling systems are not the only evaporative cooling option, but they are the most popular. The idea is simple: water soaks the pad, then the air is pulled through the wet pad, cooling as it passes through, and replaces the hot air in the barn that’s been expelled by the fans.

Water is channelled vertically over frames containing filter pads. Air is then sucked in through the wet pads, causing the water to evaporate and the air to absorb the moisture. This process cools the air, and the heat element is extracted through the fans.

Keep in mind that pads are only part of your overall cooling system. Tunnel fans are the other, more important, part. Evaporative cooling systems (cool cells) work to enhance tunnel ventilation. The first requirement for successful cooling is airflow.

Sufficient air velocity to provide a good wind-chill effect is more important than any other item in a hot weather broiler house. Pad cooling is complementary to tunnel ventilation and relies on the large volume of airflow created by the tunnel fans to improve sensible heat loss from the birds.