By Michael Barker

With retailers and consumers wanting ever more imaginative shapes for their poultry, manufacturers are coming up with creative and efficient cutting, slicing and portioning solutions to fit the bill

Consumers, we are frequently told, shop with their eyes. But they also shop with their wallets and watches, wanting great-tasting, convenient food at an affordable price. That gives poultry processors the challenge of creating products that tick every box, and they rely on the latest cutting, slicing and portioning equipment to give them the toolbox to meet that demand.

Quality and food safety is of course non-negotiable, but manufacturers are acutely aware of the focus on the aesthetic too. “First and foremost, producers are looking to respond to customer demand by creating the most attractive products,” explains Morten Dalqvist, product manager for portioning at Marel. “Presentation should be natural with a slanted natural cut. Portioned products such as butterflies, fillets, tenders, strips, dices, nuggets and popcorn should be neatly trimmed and should look good in a tray pack or on a plate. All products must be suitable for sale in supermarkets and the retail trade, in restaurants and fast-food outlets and for use in further processed products.”

There’s a definite move towards more complex shapes, and particularly in demand right now is the hand-pulled look, according to Leighton Banner, general sales manager for FAM Stumabo UK & Ireland, who adds that the key is to combine the home-made look and feel with the top-notch hygienic requirements that are vital to avoid contamination and reputational damage.

It all ties into a trend for consumers wanting a variety of different looks, and that throws up a number of questions given the diversity of product: is it cut cooked, frozen or raw? What part is being cut? How is the salt-to-moisture ratio? Did the poultry receive a heat treatment, making it more delicate? Was it marinated through injection, or vacuum tumbling, resulting in less fibrous filets? The plethora of possibilities means different types of cutting machine should be used depending on the product and required capacity and cut shape, Banner says.

Versatility is therefore key, and that’s why modular systems have become popular. “Flexibility is important for food processors, as downtime costs money and efficiency is, more than ever, king,” Banner continues. “This is why our machines are quick and easy to disassemble and sanitise. But that is also why we offer different cutting techniques specifically for the poultry processing industry, enabling producers to achieve a high-quality cut on poultry, no matter the characteristics and pre-process. Because it is an upside-down world if you, as a producer, have to adapt your complete line because your cutting solution just isn’t cut out to do the job.”

Efficiency is another key factor for processors, and Bryan Clapham, marketing manager at Cutting Edge Services, highlights the fact that improving speed and efficiency is often a key requirement for poultry customers, not only when it comes to new machinery but also through improving processes and edge maintenance practices. “It’s often the simpler solutions that we deliver with our services and products, such as keeping our customers’ knives sharp or their equipment well maintained, which delivers the greatest results,” he points out. “However, we are always looking to keep ahead of the changing landscape in the industry, and the new solutions that we are bringing to market are designed not only to improve efficiency, productivity and quality, but to meet the future challenges that our customers will face as well.” For Cutting Edge, that means a range of table-top and compact cutting machinery, as well as some as-yet under wraps new technology that the company says will “transform the industry”.

Efficiency means speed too, and Dalqvist says that each new generation of portion cutters is faster than the last, adding that for overall efficiency levels, a dual-lane setup with independent cutting options for each lane represents a major leap forwards as it allows different products with various cutting angles to be cut simultaneously.

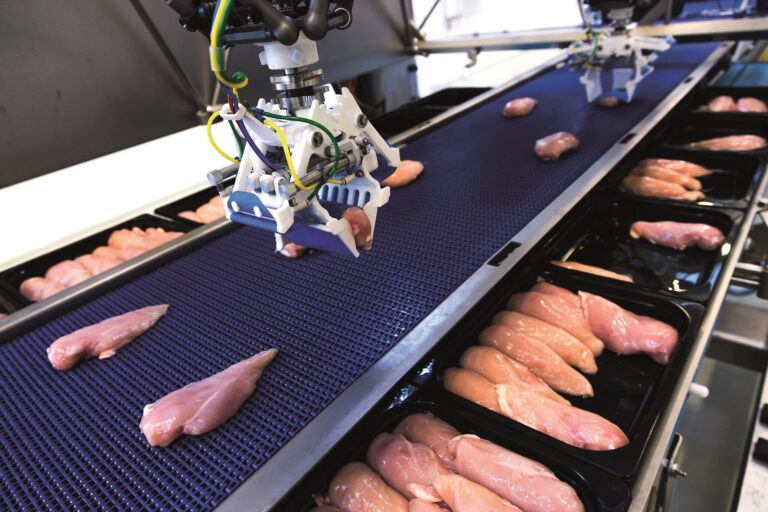

At a time when the labour supply is at a premium, machinery plays a vital role in helping processors manage the workload. Dalqvist cites the example of Marel’s Poultry Automated Nugget Line as a solution developed to make labour-intensive nugget portioning less dependent on human intervention, with manual operators only needed for quality control. The system consists of two I-Cut 22 machines, SpeedSort, SingleFeed and StripPositioner. The line, which Dalqvist explains can save at least two people per shift while increasing throughput by up to 30%, produces whole muscle nuggets cut uniformly to the customer’s fixed weight and dimensions.

For smaller butchers and processors handling a range of different meats, Cutting Edge is promoting a new range of table-top and compact machinery from manufacturers Dadaux, Gaser and Mainca, which it says covers everything from slicing to compact bandsaw applications. The company says the machines offer new opportunities and the potential for smaller-scale food processors to undertake processes that might previously have been beyond them.

Also tying into the overall efficiency picture is software, as Clapham notes: “With the ‘skills gap’ and shortages in foreign labour only set to increase in a post-Brexit environment, robotics and big data have a huge part to play in the future of the industry and we intend to be at the forefront in delivering new technology and solutions to our customers.”

Dalqvist points to the Innova software being used in Marel machines: the technology knows current order requirements and then ensures that each upstream process delivers exactly the right products to the next process downstream to meet those requirements. If the quality or weight profile of incoming product changes, the software is smart enough to adapt machine settings automatically to deal efficiently with the changed profile.

Developments, like the processing machines themselves, are moving fast. And in the battle to be a cut above the rest, those suppliers who can produce the most versatile range of products in the most efficient way possible will be those taking a bigger slice of the pie.

Three new machines to give processors the edge

‘Robot with a knife’ – Marel

Manufacturer Marel has created a “robot with a knife” concept, which combines equipment so that each component takes account of the other’s performance. The integrated solution oversees all operations from cutting through to batching and styled packing. Under the approach, I-Cut 122 and RoboBatcher Flex work together to offer users high yields with low giveaway.

The coveted ‘pulled’ look – FAM

The FAM Yuran Hytec is a hygienic belt dicer designed to process poultry products into dices, strips and hand pulled-looking shreds. The machine is completely manufactured in stainless steel, and is equipped with a three-phase motor for low-energy consumption, as well as being designed for easy washdown. It has a wide range of knife spindles to give a variety of hand-pulled looks, with sizes varying from fine to medium and coarse pulls.

High-speed deboning – Meyn

Meyn has designed its Rapid automatic breast deboner for speed and convenience. The efficient and compact Meyn Rapid breast deboner M4.1 has an increased capacity, up from 4,000bph to 4,200bph, according to the company, and is suitable for fresh and matured front halves or breast caps. The machine acts as a standalone new system that minimises installation time and makes the best use of the footprint/capacity ratio.